The TD75 Type General Fixed Belt Conveyor is a high-capacity, cost-effective, and versatile conveying equipment. It is available in two configurations based on the frame structure: fixed and mobile. The conveyor belt material can be rubber, plastic, or steel.

Operating Environment: The ambient temperature range is typically -10℃ to +40℃.

Material Temperature: For standard rubber belts, the material temperature should not exceed 70℃. Heat-resistant rubber belts can handle materials up to 120℃. Belt conveyors are not recommended for materials with higher temperatures.

Special Materials: When conveying materials containing acids, alkalis, oils, or organic solvents, oil-resistant and acid-alkali-resistant rubber or plastic belts must be used.

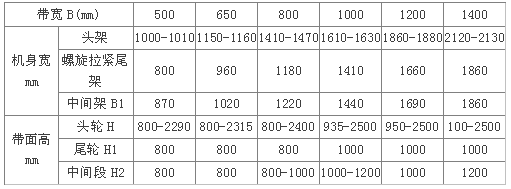

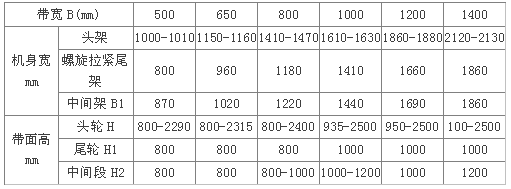

Belt Widths: Six standard belt widths are available: 500mm, 650mm, 800mm, 1000mm, 1200mm, and 1400mm.

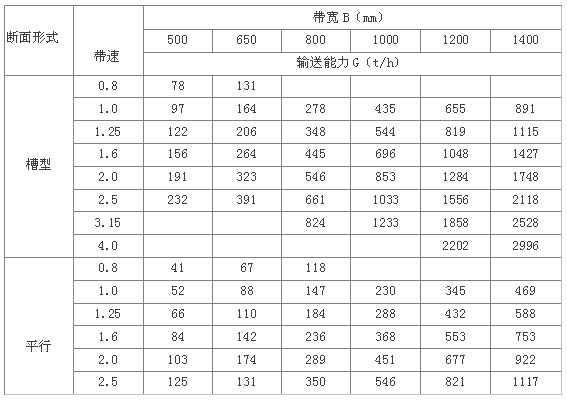

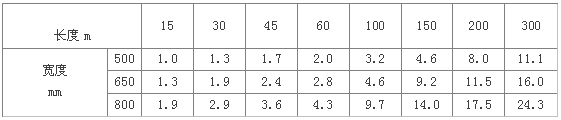

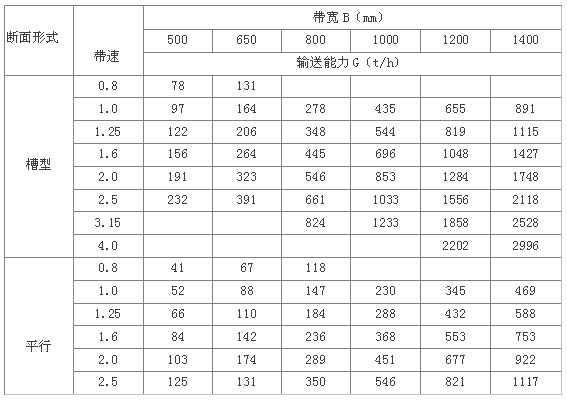

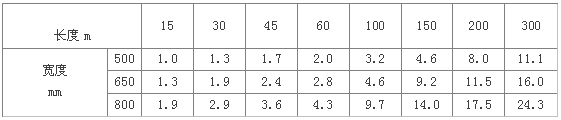

The layout of the conveyor, as well as the specific belt width, number of canvas layers, and belt thickness, should be determined through calculations based on factors such as conveying height, material type, bulk density, conveying capacity, and conveying length.

Note: The above power estimations are based on the following working conditions: normal humidity, horizontal belt speed of 1m/s, material bulk density of 1t/m³, dynamic angle of repose of 30°, one return idler cleaner, one spring cleaner, one feed chute, and consideration of acceleration resistance.

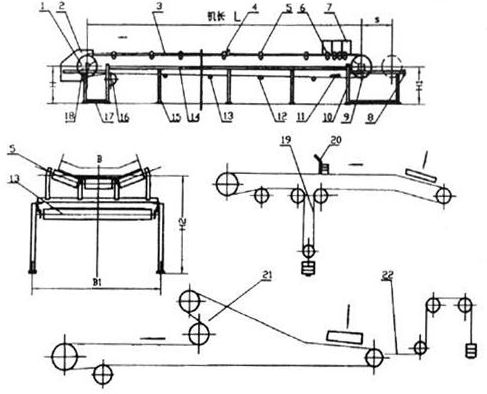

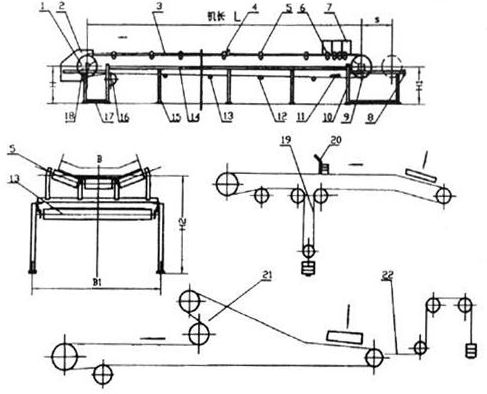

The main components are as follows:

1.Drive Drum

2.Head Cover

3.Conveyor Belt

4.Trough Self-Aligning Idler

5.Trough Idler

6.Impact Idler

7.Feed Chute

8.Screw Take-Up Device

9.Bend Drum

10.Tail Stock

11.Return Idler Cleaner

12.Return Flat Self-Aligning Idler

13.Return Idler

14.Intermediate Frame

15.Intermediate Support Leg

16.Bend Drum

17.Head Frame

18.Spring Cleaner

19.Vertical Take-Up Device

20.Plow Discharge Device

21.Tripper Car

22.Carriage Take-Up Device

V. Outline Dimension Table